Years Experience

Established in 1991, Computool Pty Ltd is a family company with over 30 years experience.

Computool has been the preferred supplier of toolmaking services and supply of complex and unusual parts for many industries including; medical, defence, security, electronic, petrochemical, pharmaceutical, automotive, cosmetics and packaging.

With several commercial clients with us for over 2 decades they have found Computool dependable and consistent with services, quality, reliable delivery and innovative solutions.

Primary Services –

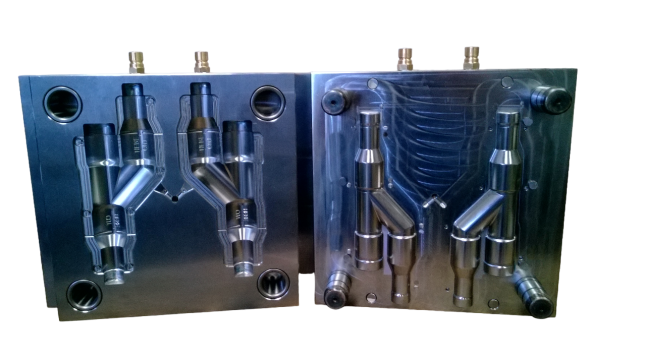

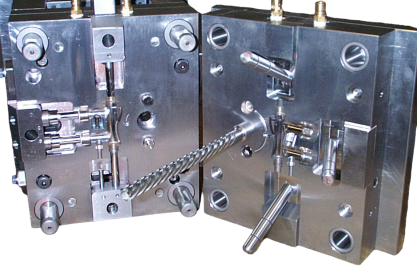

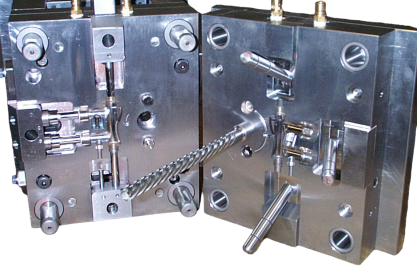

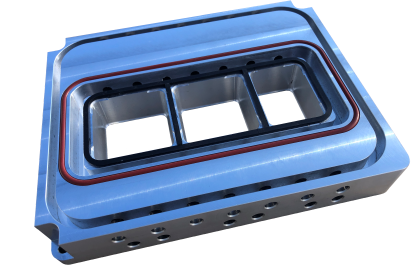

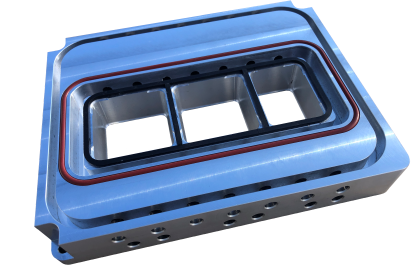

Injection Moulds

Quality moulds that will produce for many years, or a budget mould for just 200 hundred parts – we’ve much experience and proficiency in both areas. We’ll design and machine your Injection Tooling and mould the parts you need.

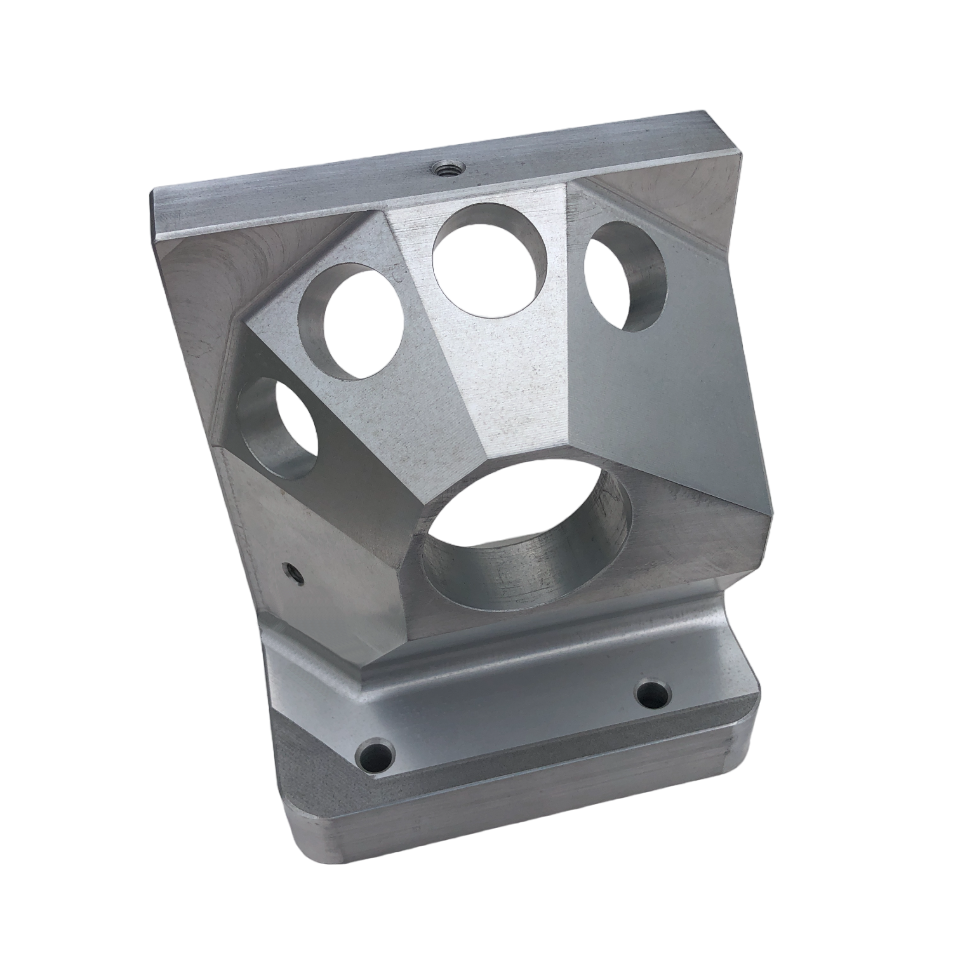

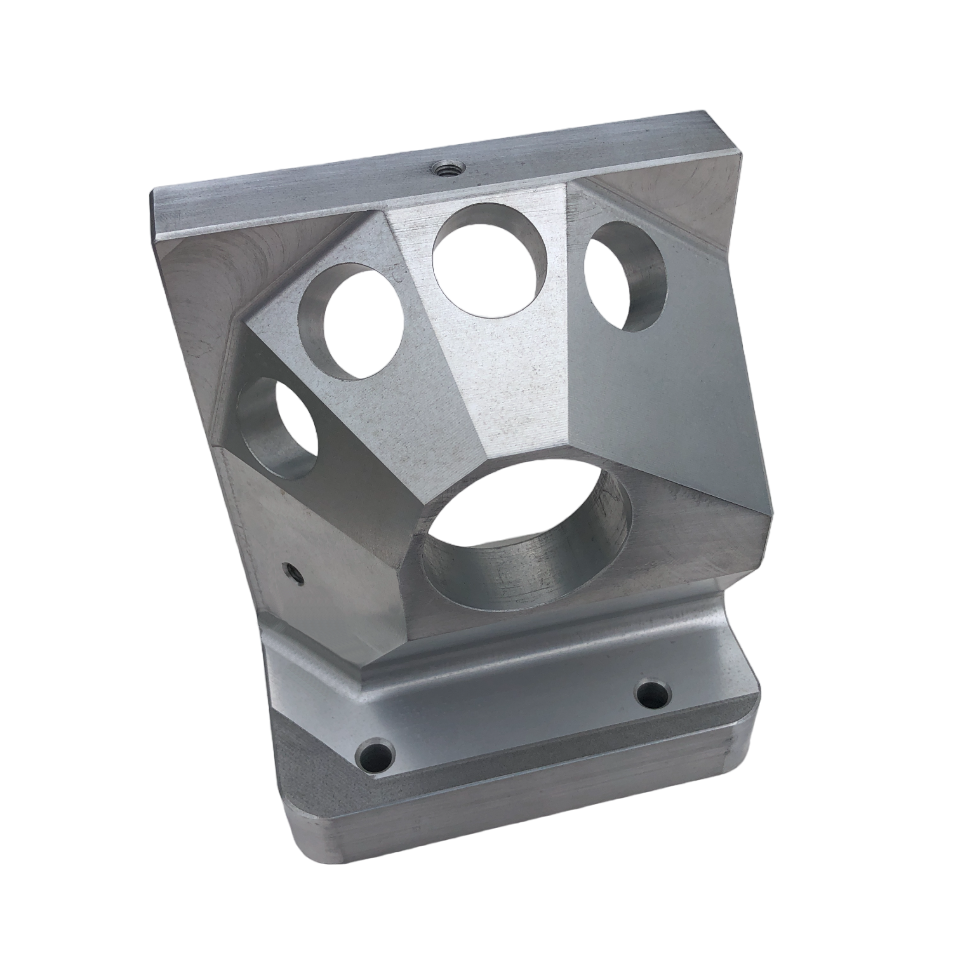

Machined Parts

Machining of all kinds of materials, including plastics, tool steels and special alloys. Packaging machinery parts, repairs and modifications. Pharmaceutical equipment, blister tooling, vacuum forming & sealing plates. One-offs and small batches.

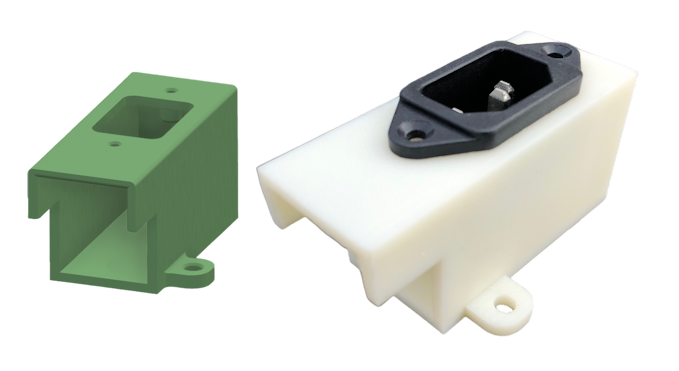

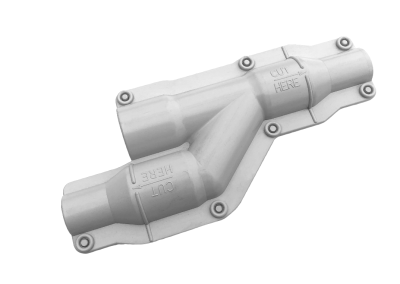

Moulded Parts

We’ll explore ideas with you, from sketches if that’s what you have, finalise your part design, produce prototypes and tooling for a moulded part. Then supply the finished moulded parts in a box, including any assembly and modify moulded parts as required.

Other Services –

To supplement core services, we offer 3D printing, Solid Modelling and design consultation services. The primary objective of good Component and Mould design is to enable the most simplified tooling possible – without sacrificing important and functional features. We’ll explain various mould functions, different finishes and their impact on tooling cost. For first-time entrants to injection moulding, see our FAQ for detailed information.

Toolmaking is much more than making precise injection moulds.

After an idea is mechanically designed, Toolmaking and precision machining is the next critical step for almost everything that is manufactured. Accurate machining of all kinds of tools and machines makes manufacturing possible. A mould or mechanical device can have many parts fitting precisely together or moving in harmony.

Toolmaking is an exacting craft because plastic moulds require very close tolerances to produce a visually pleasing, tactile and accurate component many thousands of times, year after year.

With over 30 years experience in plastic injection moulding, toolmaking and CNC machining, we can assist with every stage of the production process including moulded, printed and machined components. Small runs available too!

Examples of injection moulded or CNC machined parts. See full galleries link below.